If you agree to this disclaimer, please select “Agree” below. Further, the contents, including data and files, may be modified or terminated without notice, and Mitsubishi Materials Corporation does not warranty that any posted contents are error free.

#Flycut or end mill to remove material download#

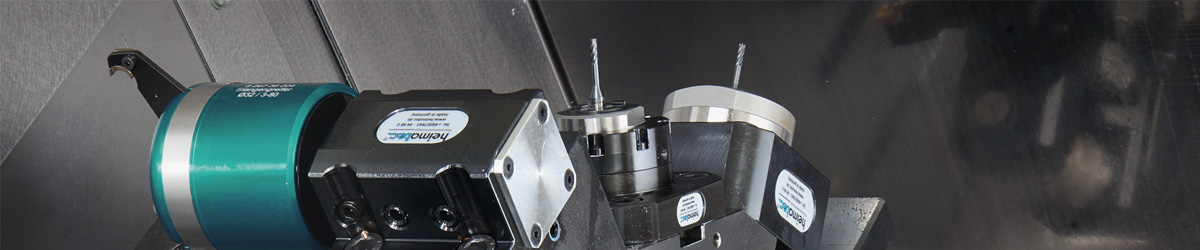

Please understand that if you decide to proceed with the next step it will be at your own discretion and responsibility.Īs far as allowed by law, Mitsubishi Materials Corporation shall not be held responsible in any way, either manifest or implied, including but not limited to legal warranty against defects, warranty of merchantability, warranty of fitness for a special purpose, or warranty against infringement of rights.Therefore, in the event that the above-stated download of the selected data or file results in the customer suffering a loss of data or damage to a computer or system, Mitsubishi Materials Corporation shall not be held in anyway responsible for said loss or damage. Rotation DirectionĮvery tool – except those designated as left-hand, like a left-handed tap – will rotate in a clockwise direction when viewed looking down at the part from the machine’s spindle.Be sure to read the following before downloading the data or file you selected. Insert solid carbide spoilboard plunging, surfacing, planing, flycutting & slab levelerCNC router bit great for cutting large surface areas and surface. The principles of rotation direction, chip formation, chip load, and milling orientation will travel with you throughout your machinist career. A close up of how much material this tool can remove. Whether you have an HSS or carbon steel end mill, all of your tools will work the same. CNC Milling and Cutting Tool Fundamentals These tools are typically ideal for cast iron, hard steels, and superalloys. Their heat and wear resistance means they can function in high heat cutting environments where other tools would not. CeramicsĬeramics are corrosion-resistant and made from aluminum oxide and silicon nitride. But the regular way to do what you want is to clamp the part to the table in several places, leaving part exposed, then flycut that part, move some of the clamps to the part you just flycut, flycut the part you moved the clamps from, et cetera. Typically carbide tools are made by sintering carbide with another metal, like tungsten, titanium, or tantalum, giving these tools high heat resistance and making them ideal for high-quality surface finishes. If you have an 8' vise you can clamp a 6' flat workpiece from the sides using Starrett hold-downs. Because of this you’ll find solid carbide used mainly in finishing applications in newer milling machines or those with less spindle wear. This material is more resistant to wear than HSS and prone to chipping instead of wearing out evenly over time. HSS tools are generally more expensive than others, but they’re built to last and provide a high material removal rate for both ferrous and nonferrous materials. Face mills use multiple inserts, which allows removing more materials at higher speeds, a fly cutter only uses one insert, which is not as fast as face milling but offers a more uniform and smooth surface. Large face mills and their inserts are expensive. Capable of removing very thin layers of material, less than 0.001 per pass. Fly cutters tend to be cheaper than face mills. This material combines chromium, tungsten, and molybdenum to give HSS improved hardness, toughness, and wear resistance over carbon steel. Amana Tool RCK-457-DLC Solid Carbide Insert Cutter Replacement Knife Blade. They have an alternating right- and left-hand tooth style for removing more material at high speeds than straight-tooth keyseat cutters. Made of solid carbide, these keyseat cutters are harder, stronger, and more wear resistant than high-speed steel for the longest life and best finish on hard material. Calculations use the desired tool diameter, number of teeth, cutting speed, and. Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth, such as an end mill or face mill. You’ll typically find this material used for low-speed operations in twist drills, forming tools, milling cutters, and turning. Carbide Staggered-Tooth Keyseat End Mills. Determine the spindle speed (RPM) and feed rate (IPM) for a milling operation, as well as the cut time for a given cut length. This is the most inexpensive material of the bunch and includes a total of 0.6-1.5% of carbon with small amounts of manganese and silicon. The most common materials you’ll encounter in CNC milling tools include: Carbon Steel Before jumping into each tool, let’s focus on what they have in common – tool material and fundamental operation.

0 kommentar(er)

0 kommentar(er)